Revitalizing City Streets: A Day in the Life of Urban Road Repairs

The Buzz and Bustle of Street Construction

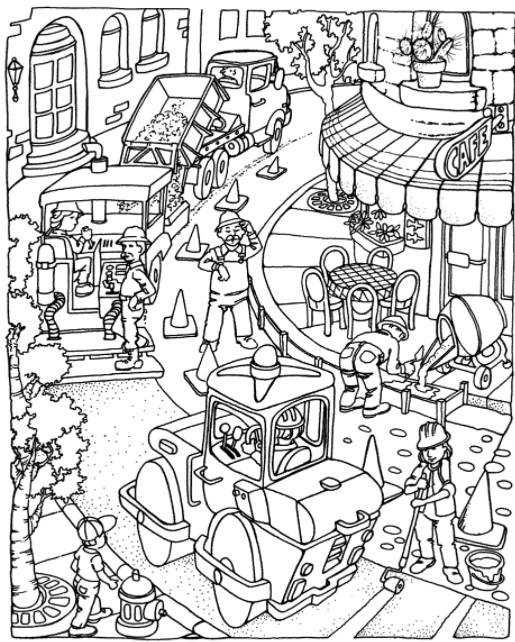

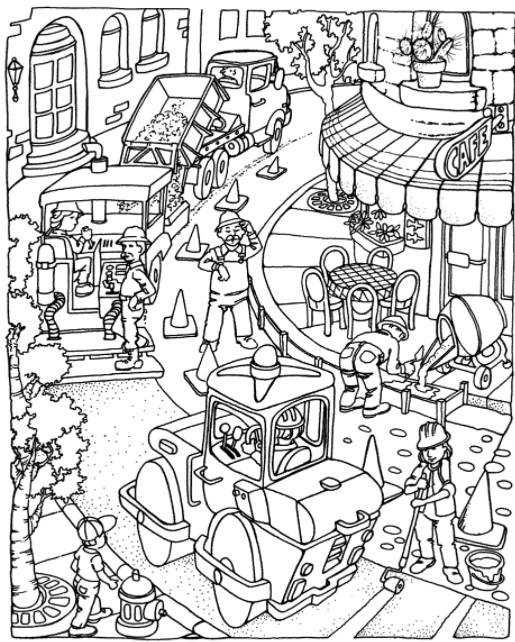

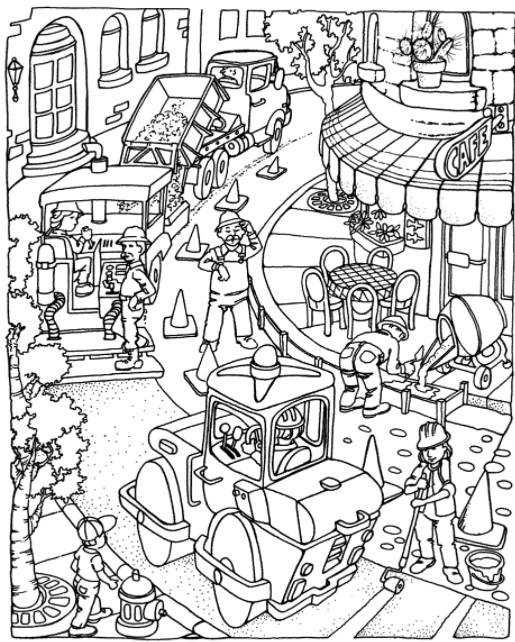

Have you ever strolled past a café terrace only to be greeted by the rhythmic hum of heavy machinery and the steady clink of shovels on asphalt? That’s exactly what we see in this dynamic snapshot: an urban street undergoing a makeover, complete with construction cones guiding traffic, workers in bright safety vests coordinating every move, and a cheerful café standing by as onlookers sip their lattes. In this article, we’ll dive headfirst into that busy scene—exploring every angle of city road repairs, from the equipment humming in the background to the safety measures that keep everyone sound and secure. Ready to rediscover the art behind that chaotic construction zone? Let’s roll up our sleeves and get started.

Understanding Why Road Repairs Matter

You might wonder, “Why should I care about a bunch of workers digging up pavement?” Well, think of roads as the arteries of a city—without them, traffic grinds to a halt, deliveries stall, and daily commutes become nightmares. Timely maintenance and repairs ensure smooth driving experiences, lower accident rates, and healthier vehicles that aren’t constantly rattling over potholes. Plus, fresh pavement can enhance curb appeal, making neighborhood sidewalks and café patios safer and more inviting.

Imagine that café seen in the photo: without proper road upkeep, customers would struggle to park or dodge uneven sidewalks. The freshly paved road outside creates a welcoming atmosphere, ensuring patrons arrive with ease, hear less engine noise, and dodge fewer dust clouds. When you peel back the cones and machinery, you’ll discover that every patch of new asphalt directly contributes to a city’s livability and economy.

Key Players in the Road Repair Crew

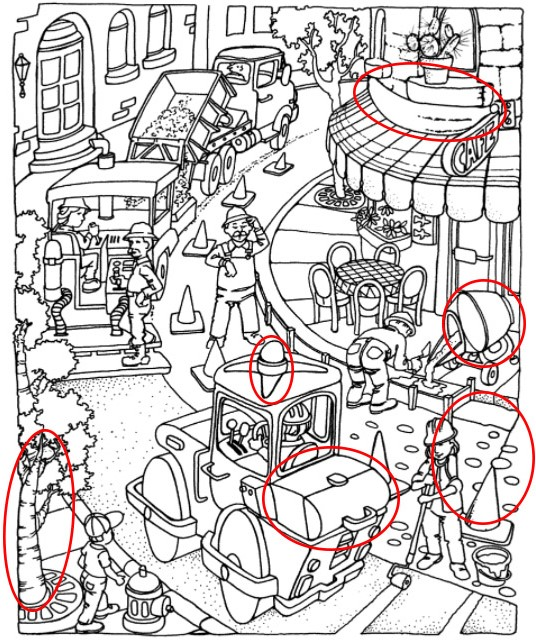

Take a moment to scan the image. Who do you see? At the forefront, a cheerful site supervisor stands with a walkie-talkie, hands on hips, orchestrating the day’s tasks. Nearby, one worker is mixing fresh concrete near the café entrance, ensuring a smooth transition between sidewalk and street. Another carefully operates a cement mixer, feeding the right proportions of sand, gravel, and binder to achieve that perfect consistency.

Then there’s the team maneuvering a hefty dump truck—it has just tilted its bed to release a fresh load of asphalt. Piles of gravel cascade onto the ground, ready to be leveled and compacted. A row of safety cones delineates the work zone, reminding passersby to proceed with caution. And let’s not forget the steamroller—an old, sturdy machine that resembles a friendly dinosaur, flattening every ridge until the road glistens like satin under the morning sun. Each person, each machine, and each tool plays a vital role—like musicians in an orchestra—harmonizing duties to transform that worn-out street into a polished thoroughfare.

Essential Equipment for Urban Road Renovation

If you’ve never stepped behind a construction fence, some of these machines might look like alien contraptions. Yet they’re indispensable for every successful project:

- Dump Trucks: These large vehicles haul demolition debris and deliver fresh asphalt or gravel. In our image, the dump truck is mid-tilt, pouring out that fresh load. Without it, crews would waste precious hours manually transporting materials.

- Cement Mixers: When walkway edges or potholes require a custom concrete patch, cement mixers come to the rescue. You can spot one near the café. It blends cement, water, and aggregates into a uniform mix, ready to be poured into damaged sections.

- Steamrollers (Compactors): After laying down new asphalt, steamrollers thud over the surface, compressing it until it’s firm and smooth. Think of it as kneading dough—if you don’t press evenly, you’ll end up with bumpy road “loaves.”

- Jackhammers and Pneumatic Tools: Sometimes, stubborn old pavement needs to be rescued with brute force. Jackhammers break up concrete and asphalt into manageable chunks so they can be hauled away. Look for workers wearing ear protection—those tools are loud!

- Safety Cones and Barriers: Bright orange cones zigzag through the work zone, guiding both pedestrians and vehicles away from potentially dangerous spots. They’re like sentinels, signaling caution and ensuring that nobody wanders into the machinery’s path.

- Hand Tools (Shovels, Rakes, Trowels): Yes, even in this high-tech setting, good old muscle power matters. Workers use shovels to spread gravel, rakes to level surfaces, and trowels to smooth fresh concrete—details that machines simply can’t achieve.

All of this equipment works in concert, ensuring that each step—from demolition to paving—flows seamlessly into the next. Without the proper gear, what should take a few days could drag on for weeks, snarling traffic and testing everyone’s patience.

Step-by-Step: How a Street Gets a Makeover

Wondering what exactly goes into that moment when a block of pavement transforms from pothole-riddled eyesore to fresh, glossy roadway? Here’s a behind-the-scenes breakdown:

- Assessment and Marking: First, city engineers inspect and mark damaged areas. They measure pavement thickness, note utility lines, and decide which sections need full-depth replacement versus simple resurfacing. Think of it like diagnosing a patient: you can’t treat a wound without knowing how deep it goes.

- Traffic Control Setup: Before any digging, the crew places those safety cones and barriers, rerouting traffic and ensuring sidewalk detours if needed. A flagger stands at a strategic point, ready to halt incoming vehicles when heavy equipment needs to pass. Without proper traffic control, chaos erupts—cars could crash into machinery, or pedestrians might wander into a fresh concrete area.

- Demolition and Removal: Next comes the loud part: jackhammers break apart the old pavement. Large chunks of asphalt and concrete are scooped into dump trucks, clearing the slot for fresh materials. This is where earplugs and dust masks become absolute essentials.

- Base Preparation: Once the old surface is gone, workers grade the exposed base, ensuring a stable foundation. They may add a layer of crushed stone or gravel, particular to the city’s engineering standards, to guarantee proper drainage and prevent dips in the future.

- Formwork and Concrete Pouring: For sidewalks, curbs, or patches near building entrances—like that café patio—wooden forms get set up to contain fresh concrete. When the cement mixer finishes its swirl, crews pour the mix into the forms, smoothing it with trowels until it resembles a tabletop mirror.

- Asphalt Laying: In larger sections of the road, hot asphalt (a mixture of aggregate and bitumen) is delivered straight from a nearby asphalt plant. The dump truck tips it into a paving machine, which spreads it evenly over the base. Behind the paver, hand crews quickly fill edges and trim corners so no gap exists between the new asphalt and adjacent surfaces.

- Compaction: Fresh asphalt is deceptively fragile—run over too soon by heavy traffic, and it will crumble. That’s why steamrollers pass over the surface multiple times, once in one direction and again at 90 degrees, until the asphalt compacts to the correct thickness and density. This step is crucial for a long-lasting, crack-resistant road.

- Finishing Touches: After the material hardens, crews paint road lines, install new traffic signs, and return signage to its place. They clear away cones once traffic can flow safely, and any remaining debris is carted off. The final sight is that shiny, jet-black pavement, gleaming like a freshly iced cake under the sun.

Safety First: Protecting Workers and Passersby

In this bustling scene, safety isn’t an afterthought—it’s the central pillar. Imagine if workers skipped cone placement or failed to wear their helmets: accidents would happen in seconds. Here are the key safety measures you’ll spot (or should spot) on any construction site:

- High-Visibility Clothing: That neon yellow or orange vest isn’t just a fashion statement—it’s a lifesaver. When a truck backs up or a loader swings its arm, the operator spots the worker’s vest instantly, reducing the chance of tragic collisions.

- Hard Hats and Protective Gear: Helmets, steel-toe boots, and gloves protect from falling debris, hot asphalt splashes, and unexpected slips. In our image, you can see every worker sporting a hard hat—non-negotiable in any work zone.

- Barricades and Warning Signs: From “Men at Work” signs to electronic arrow boards, these signals tell motorists, cyclists, and pedestrians where to detour. Without clear signage, confusion reigns, and accidents spike. In the photo, the café tables remain open, suggesting sidewalk access is maintained safely—another nod to careful planning.

- Strict Traffic Control: A flagger stands near the dump truck, thumbs raised to pause traffic. That balance between moving heavy machinery and letting cars pass is orchestrated by trained individuals using standardized flags and gestures. When you see a worker extending their arm diagonally upward, it’s your cue to bring your vehicle to a smooth stop.

- Dust and Noise Management: For dusty demolition phases, water trucks occasionally spray the loose aggregate to reduce airborne particles. That helps workers’ respiratory health and keeps nearby café patrons from inhaling gritty dust. Ear protection is equally vital, especially when jackhammers puncture the air with deafening thumps.

If every worker follows these protocols diligently, the construction zone runs like a well-oiled machine—minimizing hazards and maximizing efficiency.

Walking the Fine Line: Minimizing Disruption for Businesses and Residents

Not every street to be repaired is a ghost town; often, shops, cafés, and homes nestle right at the edge of the work zone. So how do crews keep daily life humming while hammering away at pavement? The key is communication and scheduling:

- Early Coordination with Local Businesses: Town crews typically inform shop and café owners weeks in advance—outlining the planned start date, expected duration, and alternate entrance routes. In our scene, look at how the café’s outdoor tables remain intact, strategically placed away from fresh concrete. That shows respectful collaboration between the construction team and business owners.

- Night or Off-Peak Work: To avoid gridlock during rush hour, many crews tackle main roads overnight or early in the morning. Less traffic means faster progress, and business owners can open on time with minimal interference. Of course, night work requires additional lighting and even stricter safety measures to protect fatigued drivers and workers.

- Temporary Walkways and Signage: Whenever sidewalks are blocked, crews erect temporary wooden pathways or designate alternate crossings. They paste bright signs that clarify which route to follow, ensuring pedestrians—parents with strollers, elderly folks, or partners walking to the café—aren’t left feeling stranded. Well-placed cones guide them safely around the work zone.

- Regular Progress Updates: Community bulletin boards, local newspaper announcements, or social media updates keep everyone informed. When neighbors know “Tuesday we reseal the intersection,” they can plan errands accordingly—perhaps grabbing their morning coffee at the café before the jackhammers start. That kind of transparency builds goodwill, so locals view crews as allies, not intruders.

When this coordination happens seamlessly, construction and commerce coexist—much like the café’s clinking coffee cups blending with the distant hum of the steamroller.

Long-Term Benefits: Why the Noise and Dust Are Worth It

After the last cone is removed and the final line painted, you might wonder, “Was all that racket worth it?” Absolutely. Here’s why:

- Extended Pavement Life: Properly laid asphalt can last 15–20 years, compared to a few years if patchwork is rushed. Long-term durability means fewer disruptions down the line—and that’s far less headache for drivers, cyclists, and businesses.

- Improved Safety: Smoother roads reduce tire wear and tear and lower the risk of accidents caused by potholes or uneven surfaces. Biking or walking with confidence becomes easier—no more dodging cracks or skirting around torn concrete.

- Enhanced Aesthetics: Fresh, dark pavement has an instant facelift effect—streets look cleaner and more modern. That pleasant visual upgrade often encourages foot traffic to local shops and eateries, boosting the neighborhood’s economic vitality.

- Better Drainage: When crews properly reshape curbs, install new catch basins, or grade drainage slopes, heavy rainwater flows away from sidewalks and homes. That prevents flooding, erosion, and basement water damage—benefiting everyone for years to come.

- Environmental Gains: Modern asphalt mixes often include recycled materials—old pavement scraps get ground and reused, reducing landfill waste. Plus, smooth roads allow vehicles to use fuel more efficiently, cutting down on carbon emissions over time.

So, while the jackhammers and mixers may roar temporarily, the long-lasting dividends—safer streets, a revitalized neighborhood, and a more eco-friendly footprint—make it all worthwhile.

Conclusion: Embracing the Transformation Beneath the Cones

The next time you sip coffee at a sidewalk café and spot orange cones and rumbling machinery, remember: you’re witnessing a vital transformation. Those dedicated workers, from the flagger holding traffic to the operator guiding the steamroller, are weaving together safety, efficiency, and community well-being in every shovelful of asphalt. That café in the photo isn’t just a backdrop—it’s a testament to the delicate balance between commerce and construction, daily life and progress.

Urban road repairs might seem chaotic at first glance, but behind that clutter of cones and heavy machinery lies an orchestra of planning, equipment, and teamwork. The roar of trucks, the hiss of mix, and the whir of rollers all translate into smoother rides, safer sidewalks, and a more vibrant streetscape. So next time you pass by a construction site, tip your hat (or your coffee cup) to the unsung heroes working under hard hats—they’re not just fixing roads; they’re paving the way for a brighter, smoother tomorrow.